- Monday 8:00AM - 5:30PM

- Tuesday 8:00AM - 5:30PM

- Wednesday 8:00AM - 5:30PM

- Thursday 8:00AM - 5:30PM

- Friday 8:00AM - 5:30PM

- Saturday 8:00AM - 12:00PM

- Sunday Closed

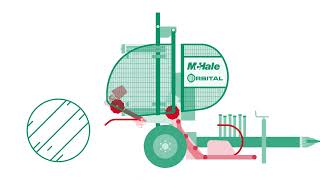

2025 McHale Orbital High Speed Twin Dispenser Round Bale Wrapper

Orbital High Speed Twin Dispenser Round Bale WrapperThe McHale Orbital high-speed round bale wrapper harnesses the proven vertical wrapping ring technology used in the McHale Fusion such as the patented high-speed transfer system and the patented tip roller to deliver a high-output, low-maintenance wrapper which is capable of keeping up with multiple balers. These patents ensure high output and superior levels of forage quality are achieved. |

| The McHale Orbital is a high-speed round bale wrapper which delivers an even and consistent overlap and achieves optimum levels of fodder preservation and quality. |

McHale OrbitalWatch the video for the McHale Orbital twin dispenser high-speed round bale wrapper. |

McHale Set-Up Series Part 2 – McHale OrbitalTune into the second of our three part series to find out how McHale experts setup and adjust their machines to save money and obtain maximum efficiency and output. To view the subtitles in your preferred language, please click on the settings icon in the bottom right hand corner of the video and select the required language. |

The Customer ExperienceVincent Stapleton is a contractor from Thurles, Co. Tipperary where he operates a McHale Orbital High Speed Round Bale Wrapper. He spoke to us about the evolution of his business as well as his experiences with the McHale brand over the last 25 years. |

McHale Orbital Bale TransferAs the lift arm moves the bale onto the wrapping platform, the front roller pivots down to reduce the height the bale has to travel to the wrapping position. This design allows the bale to transition in a smooth and quick manner that is stress-free on the machine. The lift arm also has the ability to carry a bale while another is being wrapped, delivering higher output. |

| Fully Automatic Operation | Patented High-Speed Bale Loading | High-Speed Vertical Wrapping Ring |

| Wrap Bales from 1.1m – 1.45m (3’7″ to 4’9″) | Proven and Reliable Cut & Hold System | Gentle Bale Tip after Wrapping |

| Film Break Sensors |

Facility to Wrap with One Roll

Easy Film Loading |

Expert Plus Control Console |

| Transport Length | 4.35 m (14′ 3″) |

| Transport Width | 2.74 m (9′)* |

| Transport Height | 3.0 m (9′ 3″) |

| Height to Top of Rollers | N/A |

| Weight (unladen) | 2400 kg (5391 lbs) |

| Bale Size | 1.48 m (4’9″) |

| Aluminum Dispensers | 2 x 750 mm |

| Film Stretch | 70% Standard 55% Optional |

| Wrapping Speed (up to) | 40 rotations/min |

| Wrapping System | Wrapping Ring (Fusion System) |

| Protection Mechanism | Relief Valve |

|

Lift Capacity

@ 170 bar |

1200 kg (2646 lbs) |

| Driver Control | Expert Plus Control Console |

| Operation | Automatic & Manual |

| Radio Remote Control | Optional |

| Film Roll Capacity | X 8 (2+6) |

| Cut & Hold | Yes |

| Bale Wrap Monitor | Yes |

| Road Lights | Yes |

| Greasing Points | 22 |

| Wheel Dimensions | Standard: 380/55-17 Optional: 480/45-17 |

| Axle | 6 Stud |

| Attachment to Tractor | Pin Hitch |

| Min. Hydraulic Requirements | 35 l/min @ 170 bar |

| Hydraulic Connections | 2 x 1/2″ QR’s Open or Closed Centre or Load Sensing |

| Electrical Requirements | 12v 10A EuroPlug or Direct from Battery |

| Minimum hp Requirement | 45 kW / 60 hp |

| Name | Link |

| Download Product PDF | Download |